Drawing Parts from Special Metal Components

Prototypes & Small Series

At Mokawa, we support you from feasibility checks through to prototype and small-batch production — with a focus on precision manufacturing, clean documentation and cost-effective implementation.

Key Questions for Your Project

- What temperature resistance do your components need — continuous and short-term?

- What media are involved (acids, alkalis, chlorides, hydrogen, halogens)?

- Which mechanical factors matter most: strength, toughness, fatigue, or creep resistance?

- What tolerances, surface finishes and sealing requirements are truly necessary?

- How many prototypes or batch sizes are planned — and how quickly are they needed?

Contents

- Definitions & Fundamentals

- Overview of Special Metals

- Applications & Typical Drawing Parts

- Manufacturing Methods for Prototypes & Small Series

- Design for Manufacturability (DFM): Making Parts Affordable

- Tolerances, Surface Finish & Quality Assurance

- Procurement & Supply Chain for Special Metals

- Costs & Economic Factors

- Project Process at Mokawa

- Practical Examples

- Checklist for Your Enquiry

- FAQ

- Conclusion & Next Steps

Definitions & Fundamentals

Special Metals – A collective term for materials with exceptional properties (e.g. high corrosion or temperature resistance, biocompatibility, vacuum suitability) and/or difficult machinability. Includes titanium, nickel, cobalt and zirconium alloys, plus refractory metals such as tantalum, niobium, molybdenum and tungsten.

Refractory Metals – Metals with very high melting points (usually above 2000 °C) and excellent high-temperature performance. Typical examples: W, Mo, Ta, Nb. Often brittle and challenging to machine or join.

Alloy – A metallic material made from at least two elements whose composition is tailored to achieve specific properties (e.g. strength, corrosion resistance, creep behaviour).

Tolerances – Permissible deviations from nominal dimensions. Typically specified as general tolerances (e.g. ISO 2768) or fits for individual dimensions. Tight tolerances increase machining time and inspection costs.

Surface Roughness (Ra/Rz) – Describes the microstructure of a surface. Smaller values mean smoother finishes — crucial for sealing, friction, wear and coating adhesion.

Overview of Special Metals

Material selection depends on operating temperature, medium, load profile, standards and economic considerations. The table below provides indicative guidance:

| Material Group | Examples | Strengths | Typical Limitations | Reference Values |

|---|---|---|---|---|

| Titanium | Ti Grade 2 (pure), Ti-6Al-4V (Grade 5) | Excellent strength-to-weight ratio, corrosion resistance, biocompatibility | Cost, harder to machine than steel, low thermal conductivity | Melting point ~1668 °C; continuous use < 400 °C |

| Nickel Alloys | Inconel® 718/625, Hastelloy® C-276 | High-temperature strength, superb corrosion resistance, creep resistance | High material cost, tool wear | Continuous use ~600–900 °C |

| Cobalt Alloys | e.g. Stellite® | Wear/heat-wear resistance, corrosion resistance, edge stability | Very tough to machine, costly | Ideal for valve seats, hot wear parts |

| Tantalum / Niobium | Pure Ta/Nb | Extreme acid resistance (HF/HNO₃ → Ta), vacuum suitability | Expensive, joining methods specialised | Melting points: Ta ~ 3017 °C / Nb ~ 2477 °C |

| Molybdenum / Tungsten | Mo, W | Refractory, excellent thermal conductivity (Mo), radiation shielding (W) | Brittle, difficult welding/forming, oxidises > 400 °C (Mo) | Melting points: Mo ~ 2620 °C / W ~ 3420 °C |

| Zirconium | Zr 702/705 | Excellent corrosion resistance in many acids/alkalis, low neutron absorption | Cost, reactivity at high temperature | Melting point ~1855 °C |

Applications & Typical Components

Chemical & Process Engineering: Nozzle inserts, mixer rods, reactor parts, sealing strips, flanges, linings (Ta, Zr, Hastelloy®).

Vacuum & Semiconductor Technology: Chamber fixtures, wafer arms, vacuum flanges (Ti, Mo, Ta).

Energy & Turbomachinery: Turbine rings, holders, exhaust components, heat shields (Inconel®, Co alloys).

Medical & Life Sciences: Clamps, brackets, contact parts (Ti Grade 5/2), corrosion-resistant reactor parts (Zr).

Oil & Gas / Offshore: Valve inserts, sealing faces, parts exposed to crevice corrosion (Duplex, nickel alloys).

Research & Prototyping: Functional samples, test benches, sensor housings.

Typical drawing parts include milled plates, turned sleeves, thin-walled sheet components, wire and spring elements, EDM-cut contours, welded/brazed assemblies, and sealing faces.

Manufacturing Processes for Prototypes & Small Series

CNC Milling and Turning (3- to 5-axis)

Suitable for a wide range of geometries with controlled accuracy and surface finish.

Tolerances: ±0.02–0.05 mm economically; ±0.01 mm achievable with effort.

Surface roughness: Ra 0.8–3.2 µm typical; Ra ≤ 0.4 µm achievable with fine finishing.

Material notes:

Titanium: Low thermal conductivity → sharp tools, rigid clamping, reduced feed rates.

Nickel/Co alloys: Tough and tool-wearing → low cutting speeds, effective cooling essential.

Refractory metals: Burr-prone; controlled parameters are key.

EDM (Wire & Sinker)

Very precise contours, fine webs and sharp internal corners.

Tolerances: ±0.005–0.01 mm; minimal heat-affected zones.

Benefit: Material hardness irrelevant — ideal for difficult-to-machine alloys.

Sheet Processing, Laser/Waterjet Cutting, Forming

Ideal for thin-walled shields, sealing strips, covers.

Tolerances: ±0.1–0.2 mm; tighter for laser micro-cutting.

Note: Waterjet preferred for heat-sensitive alloys.

Welding (TIG/Laser) & Vacuum Brazing

Titanium/Nickel/Zirconium: Shielding gas or chamber welding critical; cleanliness and heat input control essential.

Tantalum/Molybdenum/Wolfram: Vacuum brazing preferred.

Quality assurance: X-ray/ultrasonic testing, leak testing.

Grinding, Lapping, Honing

For fine finishes, precise fits and sealing surfaces.

Surface roughness: down to Ra ≤ 0.1 µm achievable.

Additive Manufacturing (AM)

Materials: Ti-6Al-4V, selected nickel alloys.

Benefits: Functional integration, weight reduction, rapid design iteration.

Post-processing: Support removal, heat treatment, precision milling.

Process Comparison Table (Reference Values)

| [] Verfahren | Wirtschaftliche Toleranz | Feinsttoleranz (mit Aufwand) | Typ. Rauheit | Bemerkung |

|---|---|---|---|---|

| CNC Fräsen/Drehen | ±0,02–0,05 mm | ±0,01 mm | Ra 0,8–3,2 µm | Sehr flexibel; stark materialabhängig |

| Drahterodieren | ±0,01 mm | ±0,005 mm | EDM‑Finish | Härte egal; exakte Innenradien möglich |

| Laserschneiden | ±0,1–0,2 mm | ±0,05 mm | materialabh. | Wärmeeinfluss beachten |

| Wasserstrahl | ±0,1–0,2 mm | ±0,1 mm | rau | Keine Wärmeeinflusszone |

| Schleifen/Läppen | ±0,01 mm | ±0,005 mm | Ra ≤ 0,1 µm | Best für Pass‑/Dichtflächen |

| Vakuumlöten | – | – | – | Für komplexe Baugruppen ideal |

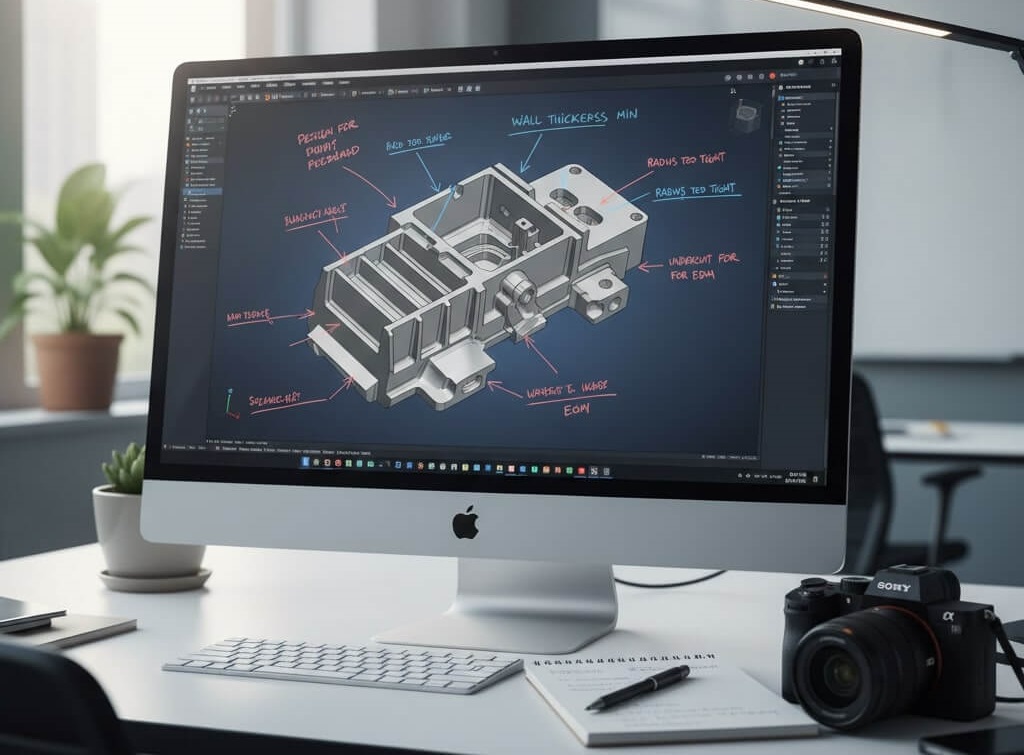

Design for Manufacturability (DFM): Making Parts Cost-Effective

DFM decisions often determine 30–50 % of the final unit cost.

Target tolerances

Tight only where functionally critical (fit, seal, motion).

Moderate general tolerances (e.g. ISO “medium”).

Standard radii and threads

Internal radii ≥ 0.5–1.0 mm ease milling and reduce EDM time.

Prefer metric threads; avoid deep blind holes.

Wall thickness & transitions

Ensure sufficient stiffness for titanium/nickel alloys.

Smooth transitions improve fatigue strength.

Material selection

Match semi-finished form (bar, plate, forged) to geometry to minimise material loss (“buy-to-fly ratio”).

Assembly thinking

Use special metals only where required; combine with standard materials elsewhere.

Design joints for stable fixing and heat flow.

Surface requirements

Specify Ra only where critical; elsewhere “as machined” is sufficient.

Lap only sealing faces, not full surfaces.

Quality Assurance & Documentation

Comprehensive measurement and documentation are essential, especially in regulated industries:

First Article Inspection (FAI) for prototypes/small batches.

CMM / 3D measurement for positional and form tolerances.

Surface analysis (contact or optical).

Material certificates: EN 10204 3.1 standard, 3.2 on request.

NDT: Ultrasonic or X-ray for welds.

Leak testing: e.g. 1 × 10⁻⁶ mbar L/s.

Cleanliness: particle and film cleanliness as per vacuum or industry standards.

Tip: Identify “Critical to Quality” (CTQ) features directly in your drawings — it saves time and focuses quality control.

Procurement & Supply Chain for Special Metals

Semi-finished materials (bar, plate, sheet, tube) often have minimum order quantities or longer mill lead times.

For prototypes, prefer available stock dimensions.

Ensure full traceability and certification.

Express sourcing possible via specialist suppliers.

Recycled content partially feasible; limited for refractory metals.

Mokawa supports you with material selection, procurement and raw part setup shortening lead times and reducing scrap risks.

Cost Factors & Optimisation Levers

Main cost drivers:

Material price & buy-to-fly ratio

Machining time & tool wear

Joining & heat processes (brazing/welding)

Quality assurance and testing

Batch size & setup time

Optimisation strategies:

Apply tight tolerances only where necessary.

Simplify geometry with standard radii/threads.

Choose the right process (e.g. EDM instead of milling).

Split assemblies — use expensive material only where functionally needed.

Think series-ready early: plan fixtures and measurement setups in prototype phase.

Engage in early DFM dialogue to avoid rework.

Project Workflow at Mokawa

Enquiry & Consultation – Understanding your requirements, environment, and regulations.

DFM Review & Quotation – Feasibility check, cost drivers, design recommendations.

Prototype Manufacturing – Material sourcing, CNC/EDM/joining, in-process inspections.

Validation – Measurement reports, certificates, NDT/FAI.

Small-Batch Production – Stable setup, cost refinement for volume.

Documentation & Delivery – Traceability, test reports, clean packaging, on-time delivery.

Practical Examples

Chemical nozzle from Tantalum (20 pcs small series)

Medium: HF acid, tight orifices, leak-proof design.

Solution: EDM internal contours, lapped sealing surface.

Result: Service life increased severalfold vs. standard alloy.Retaining ring from Inconel® 718 (prototype + 50 pcs batch)

Requirement: continuous > 700 °C, runout and creep resistance.

Solution: 5-axis milling, heat treatment, grinding of critical fits.

Result: Dimensional stability proven under heat load.Vacuum flange Ti Grade 2 (10 pcs)

Requirement: UHV-ready, Ra ≤ 0.4 µm sealing face.

Solution: CNC turning, lapping, ultrasonic cleaning, helium leak test.

Result: Leak rate achieved; improved cleanability.

Checklist for Your Enquiry

Drawing (tolerances, CTQ features, surfaces, heat treatment)

Material (specified or by medium/temperature requirement)

Batch size & delivery timeline

Test scope (CMM, roughness, PMI, NDT, leak test)

Cleanliness and packaging requirements

Certifications (3.1/3.2, traceability, labelling)

Application conditions (medium, pH, temperature, mechanical loads)

Tip: If material is not yet fixed, describe your use case we’ll propose suitable options.

FAQ (Quick Answers)

Which special metals are available short-term?

Titanium Grades 2/5, selected nickel alloys (625/718) and molybdenum are often in stock. Tantalum/zirconium may require longer lead times.

How tight can tolerances be?

CNC: ±0.01 mm possible; ±0.02–0.05 mm economical. EDM: ±0.005 mm.

What surface finishes are realistic?

Machined Ra 0.8–3.2 µm typical; ground/lapped Ra ≤ 0.1 µm.

Can special metals be welded/brazed?

Yes — with adapted TIG/laser or vacuum brazing processes.

Do you provide material certificates?

Yes — EN 10204 3.1 standard, PMI verification on request.

What drives costs most?

Material (incl. waste), machining time, joining, inspection, batch size. Biggest savings often come from DFM optimisation.

How fast can prototypes be delivered?

Depends on material availability and complexity — we’ll advise a realistic lead time.

Do you assist with material selection?

Absolutely. Share your medium, temperature and mechanical requirements — we’ll recommend suitable alloys.

Conclusion

Special metals enable technical solutions where conventional materials fail — in chemical engineering, vacuum technology, energy, oil & gas, and research.

For reliable and economical components, clear requirements, smart design and precise manufacturing are essential.

Mokawa supports you from material selection through to prototypes and small series — with transparent quality assurance and practical DFM advice.

→ Send us your drawings and requirements for a quick feasibility, cost and lead-time check.

→ Request a DFM review to identify cost drivers and design improvements.

→ Get your quotation including inspection and documentation package (3.1/3.2, PMI, CMM report, NDT/leak tests).

Question to start: Which three requirements of your component are non-negotiable (e.g. medium, temperature, tolerance)?

Based on this, we’ll structure the optimal manufacturing and testing concept.